API

Products

Drill

pipe elevator

Casing

elevator

Drill collar

elevator

Slip

type elevator

Tubing

elevator

Sucker

rod elevator

Single

joint elevator

Elevator

links

Perfection links & Drill collar lift adaptor

Rotary

slips & Casing slips & Drill collar slips

Safety

clamps

Manual

tongs

Tubing

Spider

Roller kelly bushing

Casing bushing

|

Tubing spider

Tubing spider is designed and manufactured as per API Spec 7K "Drilling and Well

Servicing Equipment", two models of tubing spider are often asked

for: model C and model CHD, working capacity of model C is 80ton

while model CHD is 120ton.

Tubing spider is applied for drill pipe

or tubing in oil and gas drilling or workover operation. Tubing

Spider is designed for manual, compressed air, or hydraulic

operation, and can ensure the safety of personnel and equipment to

improve the efficiency of operation.

Tubing spider is made from high strength alloy steel; journal

bearings are fitted with replaceable steel bushings, all bearings

and journals are equipped with grease fittings for lubrication.

Tubing spiders are equipped with a manually operated safety latch to

positively lock the slips in their set position. The Slips, Shafts,

and Air Operating Mechanisms are protected by guards to prevent

damage caused by the elevators or other outside forces. Tubing

spider slip assemblies are machined as matched sets to ensure full

contact with pipes.

Tubing spider fitted with replaceable inserts, and the slip inserts

are self-centering full wrap around grip type with an API taper on

the diameter. The Slip has adequate safety mechanism or interlock to

prevent accidental opening of slip under load and ensuring proper

closing or seating. Tubing spiders are suitable to cover pipe range

from 2⅜" to 7⅝" OD tubular, and can be operated at rig air pressure

of 80-120 psi, rated load of Model C tubing spider is 80 ton, CHD

tubing spider is 120ton, Model C tubing spider is similar to CHD

tubing spider in configuration, only the slotted gate is different

from CDH tubing spider. Accessories including Shaft, Lifting arm,

Yoke, Taper pin, Crank Bushing, Link bushing, Air Coupling, Safety

Latch. Air Cylinder Assembly and Kit repair pneumatic cylinder are

available.

Technical

data of tubing

spider

Tubing Spider Model |

Slip Body Size |

For Pipe O.D. |

C/80ton |

3½in |

2⅜" |

60.3mm |

2⅞" |

73 mm |

3½" |

88.9 mm |

CHD/120ton |

3½in |

2⅜" |

60.3mm |

2⅞" |

73 mm |

3½" |

88.9 mm |

4½in |

3½" |

88.9 mm |

4" |

101.6 mm |

4½" |

114.3 mm |

5in |

5" |

127 mm |

5½in |

5½" |

139.7 mm |

|

Product

photo of tubing spider

|

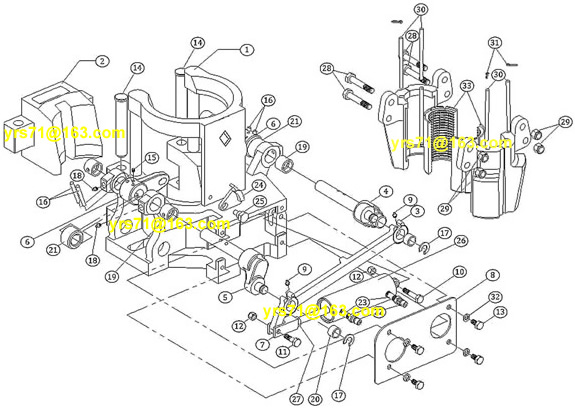

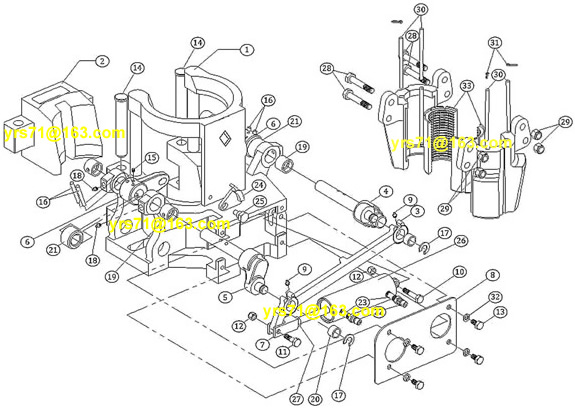

Configuration and description of

tubing spider

Configuration of tubing spider |

Description

of tubing spider parts |

|

S.N. |

Description |

Qty |

S.N. |

Description |

Qty |

1 |

spider body |

1 |

18 |

grease fitting |

2 |

2 |

semi-finished gate |

1 |

19 |

shaft bushing |

2 |

3 |

link assembly |

1 |

20 |

shaft bushing |

1 |

4 |

left hand shaft |

1 |

21 |

spacer |

2 |

5 |

right hand shaft |

1 |

22 |

flow control coupling |

1 |

6 |

lift arm assembly |

2 |

23 |

flow control coupling |

1 |

7 |

York |

1 |

24 |

safety latch |

1 |

8 |

air cylinder guard |

1 |

25 |

safety latch bolt |

1 |

9 |

grease fitting |

1 |

26 |

air cylinder |

1 |

10 |

bolt |

1 |

27 |

jam nut |

1 |

11 |

bolt |

1 |

28 |

slip bolt |

4 |

12 |

jam nut |

1 |

29 |

slip bolt nut |

4 |

13 |

set screw |

1 |

30 |

inserts set pin |

4 |

14 |

gate bolt |

2 |

31 |

inserts set pin retainer |

4 |

15 |

set screw |

1 |

32 |

set screw washer |

1 |

16 |

taper pin |

4 |

33 |

inserts |

4 |

17 |

retaining ring |

2 |

|

|

|

|

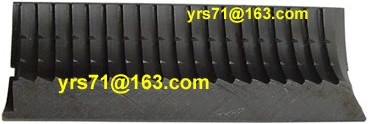

insert for tubing spider insert for tubing spider  tubing

spider adaptor tubing

spider adaptor

TS tubing spider

TS-100

tubing spider is manually operated spider, and tubing spider is made

of high quality alloy steel, heat treated and NTD for strength to

handle pipes range from 1.05” to 5½” O.D. with working capacity 100

ton.

Tubing spider is made up of two major assemblies: bowl and slip. The

bowl is machined with taper surface to match the slip bodies.

Inserts are installed in the slip bodies, each set of insert and

slip matches each size of pipe.

Technical

data of TS tubing

spider

Specifications |

Bowl size |

Size

range |

Bowl

opening |

Bowl

flange

width |

Height

(with

slips) |

Height

(without

slips) |

Slot circle

diameter |

TS 3½” |

3½”Bowl |

1.05-3½” |

5¼” |

13¼” |

8¾” |

12⅜” |

10-15” |

TS 5½” |

5½” Bowl |

3½”-5½” |

6¾” |

13¼” |

8¾” |

12⅜” |

11¼”-15¼” |

Replacement part list

S.N. |

Description |

Qty |

S.N. |

Description |

Qty |

1 |

Insert keeper |

3 |

1 |

Insert keeper |

4 |

2 |

Latch pin with cotter |

1 |

2 |

Latch pin with cotter |

1 |

3 |

Latch spring |

1 |

3 |

Latch spring |

1 |

4 |

Hinge pin with cotter |

2 |

4 |

Hinge pin with cotter |

3 |

5 |

Latch |

1 |

5 |

Latch |

1 |

6 |

Latch handle |

1 |

6 |

Latch handle |

1 |

7 |

3½”×1.050" insert |

9 |

7 |

5½”×3½”insert |

12 |

8 |

3½”×1.315" insert |

9 |

8 |

5½”×4" insert |

12 |

9 |

3½”×1.660" insert |

9 |

9 |

5½”×4½”insert |

12 |

10 |

3½”×1.900" insert |

9 |

10 |

5½”×5" insert |

12 |

11 |

3½”×21/16"

insert |

9 |

11 |

5½”×5½”insert |

12 |

12 |

3½”×2⅜" insert |

9 |

|

|

|

13 |

3½”×2⅞" insert |

9 |

|

|

|

14 |

3½”×3½”insert |

9 |

|

|

|

|

Product

photo of TS tubing spider

|

|

tubing

spider adaptor

tubing

spider adaptor