A reliable supplier for drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, slip type elevator, single joint elevator, sucker rod elevator, elevator links, perfection links, safety clamps, rotary slips

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

API Products Perfection links & Drill collar lift adaptor |

Tubing Elevator General Tubing elevator is designed and manufactured in line with API Spec 8C Specification for Drilling and Production Hoisting Equipment, and tubing elevator can be available with DD models, TA models and BDA models. In China or Russia, CD and BD tubing elevators are often asked for. DD models, TA models and BDA models tubing elevators are center latch elevator, while CD tubing elevator is side door model, BD tubing elevator is a special tubing elevator designed and popular in China. DD Tubing Elevator DD tubing elevators are conventional collar type center latch elevators for handling tubing in oil and gas drilling operation, DD tubing elevators are cast from high quality alloy steel, heat-treated, NDT and MPI. The rated load is 125ton, and cover pipe sizes from 2⅜" to 4½" OD, IU or EU, each tubing elevator is 1.5 times of the working load tested. DD tubing elevators are constructed in two halves of practically the same weight for better balance, and have a latch mechanism for the two halves at the center with latch and lock combination with a safety latch lock, DD tubing elevators are equipped with easy operating handles, link ears conform to API elevator links, handles are at rear and can be properly balanced while operating, API monogram in conjunction with numbers, product series numbers are die stamped on shoulders of tubing elevators for tracing, and tubing elevators shoulders are die stamped with size of tubing and rated working capacity. Manufacturer’s name plates are provided on bodies of tubing elevator, warranty for tubing elevators are listed in tubing elevator manual.

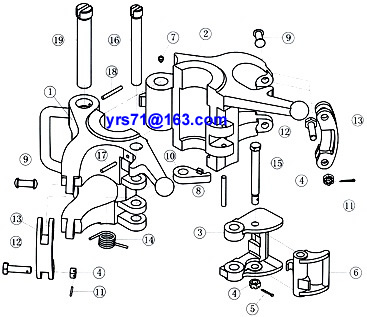

Configuration and Description of DD tubing elevator

Configuration and exploded figure for DD tubing elevators are the same for diffrent dimension or working load of elevator. Body and door are not used as replacement parts, others are replacement parts. Replacement parts of DD tubing elevators offered by Taixing Company cannot be interchangeable with those tubing elevators supplied by other manufacturer.

TA Tubing Elevator TA tubing elevators are conventional collar type center latch elevators for handling tubing in oil and gas drilling operation, TA tubing elevators are cast from high quality alloy steel, heat-treated, NDT and MPI. The rated loads rang from 100ton to 150ton, and cover pipe sizes from 2⅜" to 4½" OD, IU or EU, each tubing elevator is 1.5 times of the working load tested. TA tubing elevators are constructed in two halves of practically the same weight for better balance, and have a latch mechanism for the two halves at the center with latch and lock combination with a safety latch lock, TA tubing elevators are equipped with easy operating handles, link ears conform to API elevator links, handles are at rear and can be properly balanced while operating, API monogram in conjunction with numbers, product series numbers are die stamped on shoulders of tubing elevators for tracing, and tubing elevators shoulders are die stamped with size of tubing and rated working capacity. Manufacturer’s name plates are provided on bodies of tubing elevator, warranty for tubing elevators are listed in tubing elevator manual.

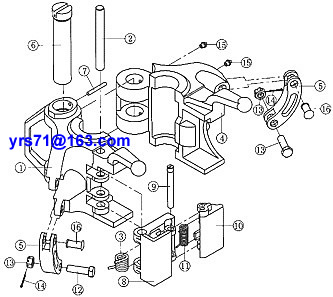

Configuration and Description of TA tubing elevator

Configuration and exploded figure for TA tubing elevators are the same for diffrent dimension or working load of elevator. Body, door and latch are not used as replacement parts, others are replacement parts. Replacement parts of TA tubing elevators offered by Taixing Company cannot be interchangeable with those tubing elevators supplied by other manufacturer. BDA Tubing Elevator BDA tubing elevators are conventional collar type center latch elevators for handling tubing in oil and gas drilling operation, BDA tubing elevators are cast from high quality alloy steel, heat-treated, NDT and MPI. The rated loads rang from 65ton to 100ton, and cover pipe sizes from 2⅜" to 3½" OD, IU or EU, each tubing elevator is 1.5 times of the working load tested. BDA tubing elevators are constructed in two halves of practically the same weight for better balance, and have a latch mechanism for the two halves at the center with latch and lock combination with a safety latch lock,BDA tubing elevators are equipped with easy operating handles, link ears conform to API elevator links, handles are at rear and can be properly balanced while operating, API monogram in conjunction with numbers, product series numbers are die stamped on shoulders of tubing elevators for tracing, and tubing elevators shoulders are die stamped with size of tubing and rated working capacity. Manufacturer’s name plates are provided on bodies of tubing elevator, warranty for tubing elevators are listed in tubing elevator manual.

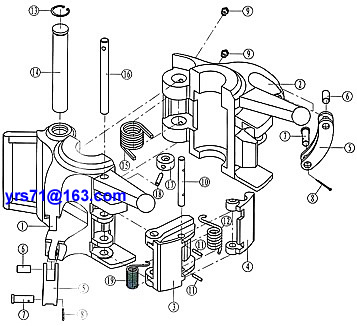

Configuration and Description of BDA tubing elevator

Configuration and exploded figure for BDA tubing elevators are the same for diffrent dimension or working load of elevator. Body, door and latch are not used as replacement parts, others are replacement parts. Replacement parts of BDA tubing elevators offered by Taixing Company cannot be interchangeable with those tubing elevators supplied by other manufacturer. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||