API

Products

Drill

pipe elevator

Casing

elevator

Drill collar

elevator

Slip

type elevator

Tubing

elevator

Sucker

rod elevator

Single

joint elevator

Elevator

links

Perfection links & Drill collar lift adaptor

Rotary

slips & Casing slips & Drill collar slips

Safety

clamps

Manual

tongs

Tubing

Spider

Roller kelly bushing

Casing bushing

|

Sucker rod elevator

Sucker rod elevator is designed and manufactured

in line with API Spec 8C “Specification for Drilling and

Production Hoisting Equipment”, Sucker Rod

Elevators are reversible type elevators to handle sucker rods in oil

extraction or work-over operation, these sucker rod elevators are equipped

with easy operating front and rear latches to ensure that sucker rods can be

released quickly and easily, by thumb and finger press alone, at either the

front or rear of the body, sucker rod elevators solid bodies are cast from high quality alloy steel and

bails are forged integrally from high quality alloy steel to ensure long service life, elevator body is fully heat-treated, bodies

of sucker rod elevators are machined to close tolerance and suitable for

handling sucker rods size range from ⅝" to 1¼" and the rated load are 15ton and 25ton. Sucker rod elevators can handle hollow type sucker

rod and will not bend or kink sucker rods under heavy load. Bodies of sucker

rod elevators are reversible to ensure that two sides of elevator body can

bear load. Sucker rod elevators bear API monogram as per API requirements,

and marked with size, rated working capacity on and product series nos

sucker rod elevator bodies to tracing, warranty of sucker rod elevators is

12 months from being in field service or 18 month from being dispatched.

Technical data of sucker rod

elevators are as follows:

Specification |

Elevator

Bore Dimension

(mm) |

Suck Rod Size

(in) |

Rating Load

ton |

CDQ(S) 19/(load) |

19 |

⅝ |

15

25 |

CDQ(S) 23/( ) |

23 |

¾ |

CDQ(S) 26/( ) |

26 |

⅞ |

CDQ(S) 29/( ) |

29 |

1 |

CDQ(S) 33/( ) |

33 |

1⅛ |

CDQ(S) 36/( ) |

36 |

1¼ |

|

Sucker

rod elevator product photo |

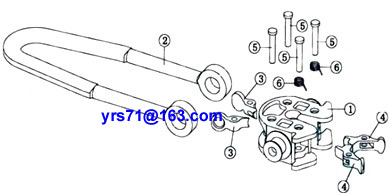

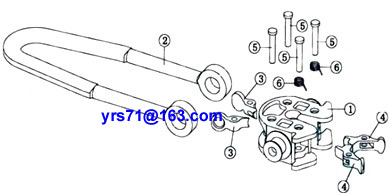

Configuration and Description of sucker rod elevator

|

Description of each item

S.N. |

Description |

Qty |

1 |

Body |

1 |

2 |

Bail |

1 |

3 |

Front latch |

2 |

4 |

Rear latch |

2 |

5 |

Pin |

4 |

6 |

Spring |

2 |

|

Operation

Sucker rod elevator hangs from the sucker rod hook, which is attached to the traveling block or the service or drilling rig. The drawworks of the rig move the elevator up and down the rig’s derrick to install and remove sucker rod. The elevator may also be used on or around the rig floor for handling sucker rod.

To attach the elevator to the sucker rod, the elevator operator stands on one side of the sucker rod with the elevator on the opposite side. The operator reaches around the sucker rod with one hand on either side of the sucker rod. The elevator is gripped by the bail, and the operator pulls the elevator to the sucker rod, so that the sucker rod is automatically latched in the center of the elevator. It is important for the elevator operator to visually verify that the sucker rod is completely inside the elevator and that the latch retainers are in place, or premature release of the sucker rod could occur resulting in bodily injury and/or dropping the sucker rod down the well requiring fishing of the dropped sucker rod string.

Elevator Inspection

Visually inspected sucker rod elevator on a daily basis for corrosion and damaged components and remove all external dirt and grease daily. Examine sucker rod elevator bail for deformation. Not to use sucker rod elevator with excess wear of ⅛".

Test the operation of the elevator latch mechanism daily.

Not to grind or remove metal from any surface of the

elevator.

Inspect daily for any visual evidence of external cracks. If visible cracks that indicate potential failure appear. Then remove sucker rod elevator immediately from service.

Grease pins to maintain smooth operation.

Magnetic particle inspect sucker rod elevator body on an annual basis for indications of cracking |